Grating Solutions in Industrial Design: A Standards-Driven Approach

- gokul raj

- Apr 7

- 3 min read

Gratings are essential components in many industrial and infrastructure projects. From platforms and walkways to drainage and marine structures, their role in safety, ventilation, and structural performance is critical. This post outlines everything worth knowing about gratings—backed by Australian standards and Sharcon’s approach to reliable detailing.

What Grating Really Is ?

Grating is an open-grid structure formed from parallel and cross bars, used to create safe, load-bearing surfaces while allowing air and liquid flow. These are commonly found in:

Walkways and access platforms

Stair treads

Maintenance zones

Drainage covers

High-security areas

The balance of strength, drainage, and slip resistance makes gratings ideal for both industrial and architectural applications.

Types of Grating

Based on Material:

Mild Steel Grating – Strong, affordable, and widely used in industrial settings.

Stainless Steel Grating – Highly resistant to corrosion; ideal for marine and hygiene-sensitive environments.

Aluminum Grating – Lightweight and durable; frequently used in offshore applications.

FRP (Fiberglass Reinforced Plastic) – Non-metallic and chemical-resistant; suitable for corrosive environments like chemical plants.

Based on Manufacturing Process:

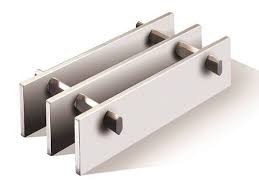

Welded Grating – Bars are welded at each intersection for maximum strength and durability.

Press-Locked Grating – Mechanically locked without welding; preferred for clean, aesthetic finishes.

Swage-Locked Grating – Crossbars are mechanically swaged into load-bearing bars to ensure a tight fit.

Expanded Metal Grating – Manufactured from a single sheet of metal cut and stretched into a mesh pattern; lightweight and economical.

Relevant Australian Standards

Sharcon adheres strictly to Australian standards to ensure grating components meet all safety, load-bearing, and corrosion-resistance requirements.

Standard | Purpose |

|---|---|

AS 1657:2018 | Governs design and installation of fixed platforms, walkways, stairways, and ladders. |

AS/NZS 4680:2006 | Specifies hot-dip galvanizing processes for corrosion protection. |

AS 3996:2019 | Provides load classifications (Class A to G) for access grates. |

AS 1428.1:2021 | Outlines accessibility compliance, including grating opening limitations (max 13 mm). |

Components of Steel Grating

Grating systems are composed of the following essential parts:

Load-Bearing Bars – Carry the structural load.

Cross Bars – Provide lateral stability and prevent sagging.

Edge Banding – Reinforces the perimeter and adds rigidity.

Fixing Clips – Secure the grating to underlying structures, preventing movement.

Each component is designed and detailed to work together, ensuring safe and reliable installation.

Typical Applications

Gratings are employed in a wide range of scenarios across industries:

Industrial Flooring and Walkways – Strong, ventilated surfaces for safe operations.

Stair Treads – Non-slip, load-bearing steps.

Drainage Covers – Allow water passage while blocking debris.

Security Fencing and Screens – Durable barriers for high-security environments.

Offshore and Marine Structures – Corrosion-resistant surfaces that withstand harsh marine conditions.

Sharcon’s Approach to Quality Detailing

Sharcon takes a precision-first, collaboration-driven approach to detailing that enhances safety, compliance, and efficiency.

Custom grating solutions are detailed based on exact project conditions and specifications.

Australian standards such as AS 1657:2018 are embedded into every drawing.

Correct fasteners, spacing, and structural support are applied by default.

Seamless collaboration with builders and fabricators helps avoid costly rework.

Safety enhancements like anti-slip coatings, lighting access zones, and compliant handrails are integrated during the detailing phase.

Projects are delivered with efficiency and accuracy, ensuring they stay on track and within budget.

Gratings may appear simple, but they require thoughtful design, precise detailing, and compliance with strict standards. Sharcon combines technical expertise with real-world experience to ensure each project benefits from safety, performance, and lasting value.

📞 Call us: +61 478 727 338

📧 Email us: shyam@sharcon.com.au

🌐 Visit our website: www.sharcon.com.au

Comments